EV Repowering Association (EVRA) – Code Of Practice for Repowering / Converting Vehicles to Electric propulsion (EV)

The EVRA is a trade association for the Electric Vehicle conversion industry which sets standards and works with members to uphold these standards.

All members of the EVRA will ensure all their conversions comply with the Code Of Practice.

Code Of Practice Version 4. 13/03/2024

A. Process management

- Members must keep a build register which records the vehicle ID, the serial numbers of removed engines and fitted motors, the type, condition and location of battery cells/modules, type of contactors and type and location of MSD/isolator switches.

- Members must keep a register of approved suppliers and a record of supplier approvals which must include how they maintain quality, their returns policy, guarantees/warranties and how continuity of supply is maintained.

- The above information must also be included in an information pack given to the customer. This document must also give clear instructions on safe usage of the vehicle, charging procedure, and what to do if it breaks down. The document must make it clear where the safe jacking points are and where a lifting jack must not be placed. The document must also give clear instructions on how to recover a vehicle, whether it can be towed and if there are towing restrictions such as maximum speed or duration of the tow.

- On completion of the conversion a final vehicle Sign Off document must be completed and securely stored. In addition a copy must be sent to the EVRA. EVRA will make the document available to anyone with a valid requirement to see it. The Sign Off document must include evidence and results of tests on the HVIL, earth bonding faults, isolation tests, isolation monitoring etc.

- All road-going converted EV must have all the relevant documents submitted to DVLA to allow them to update the V5 document to show fuel type as electric.

- All parts must be sourced from reputable suppliers with quality standards such as ISO9001 to ensure parts meet the described specification.

- Guidance contained in ECE R 100 (latest version) should be followed. The functional guidance in ECE R 100 Part 1 is a minimum requirement, the guidance in Part 2 should be followed.

B. Warnings

- Labels must be fitted in the engine bay or a similar location which clearly shows jacking points, prohibited jacking areas, towing restrictions for vehicle recovery and location of HV isolators.

- HV components including inverters, HV junction boxes and battery packs must be clearly labelled as High Voltage. Where covers are fitted over such parts the cover must have a label indicating that HV parts are behind.

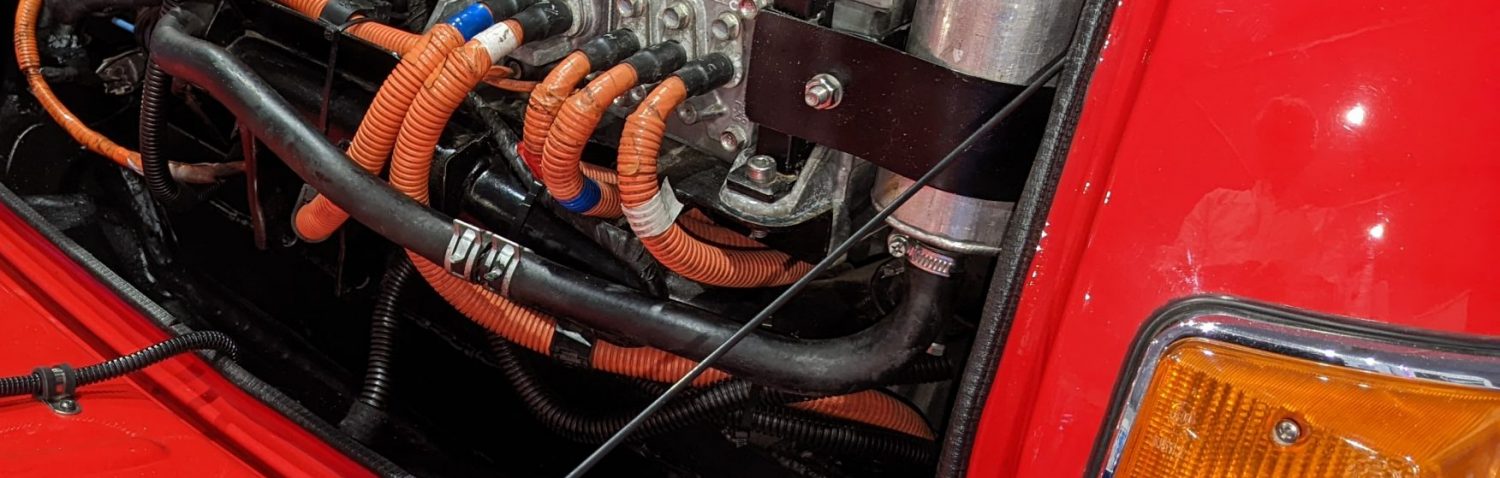

- All HV cables must be have an orange coloured outer insulation or conduit. Where covers are fitted over such cables the cover must have a label indicating that HV parts are behind.

C. Location of HV components

- No battery packs may be placed in primary crumple zones or in vulnerable areas on vehicles without identifiable crumple zones. As a guide packs should not be in front of the forward edge of the front tyres or behind the rear edge of the rear tyres.

- Packs mounted under the vehicle must not be the lowest part of the vehicle structure and must have protection against road debris hitting the packs, such as robust under-trays.

- No HV components including cables may pass through the occupied areas of the vehicle unless fully protected by a solid cover that cannot be removed without specialist tools.

D. High Voltage safety

- All HV parts must have a High Voltage Interlock Loop fitted such that if any part of the HV system is physically exposed the the packs will not energise. The HVIL must pass through all HV connectors. It is recommended that cover plates on HV junction boxes or inspection points with HV behind them are also in the HVIL by use of micro switches or connectors.

- All packs must switch off when the ignition is switched off or when a crash is detected.

- Crash detections, either by G sensor and calibrated ECU or by mechanical inertia switch must be fitted to all road going vehicles.

- All HV parts must be sealed to IP67 standard unless it can be shown to be safe with lesser protection. It must be assumed the vehicle will be driven through flood waters up to the level of the top of the tyre and all components must be resilient to water ingress from standing water at that level and also from water splash generated by driving at speed through standing water.

- It must not be possible to touch HV live components with hands, fingers or small tools such as screwdrivers without removing secure panels or fixings that require tools to remove.

E. Vehicle structure

- When modifying a vehicle its strength shall not be compromised.

- Where modifications are needed to chassis or structural parts then adequate reinforcement must be made based on a thorough understanding of the magnitude and direction of applied forces.

- Only those with the correct level of mechanical engineering skills and knowledge should attempt structural modifications.

- Where structural modifications are made the force vector calculations, static and dynamic loadings, moments of inertial etc. that have been calculated must be entered in the build register. If there is any doubt then do not modify any structural part.

- When fitting packs or motors the forces must be fed in to the vehicle structure in such as way that the mounting will not fatigue or break in repeated heavy usage or in a crash.

- Consideration must be given the the weight of the items and force generated in a crash with particular emphasis on protecting occupants of the vehicle and ensuring no heavy parts rip out of the vehicle and hit other vehicles or people.

- It is recommended to use existing engine and gearbox mounting points where possible.

F. High Voltage cables

- All HV cables and parts must be isolated from the low voltage system and chassis/body, this must be tested at at least 1000V.

- All cables must be Automotive grade with a temperature range of -30 to +50C or better. They should be tolerant of solvents and fuels as well as vibration. Domestic cabling or welding cables are prohibited.

- HV cables must have an orange outer.

- HV cables must be supported every 400mm or as recommended by the cable manufacturer in such a way that thermal expansion and contraction will not strain the cables and that the cables cannot fret or wear against any other part of the vehicle.

- Cables must not rest on surfaces loosely, such as inside of closed chassis sections, such that they could rub and wear. Cables passing through panels must be supported by a cable gland or fitting such that fretting and wear is prevented.

- All HV cables must be protected from impact from road debris, fitting in wheel arches should be avoided unless adequate shielding is in place. Cables routed under the vehicle floor must be protected by shielding of robust material that would reasonably stop road debris damaging the cables.

- HV cables outside of battery boxes and conductive enclosures such as metal distribution boxes must be shielded with one end of the shielding connected to the vehicle chassis ground.

G. Pack construction

- All battery boxes on a vehicle must be adequately strong so as to remain intact in the event of a vehicle collision. Pack structure must be adequately strong, such as EN220 Steel or CR6050 aluminium. Fragile materials such as wood and soft plastics are prohibited. Strong plastics and composites may be used for pack panelling but only in non structural parts of the pack unless it can be shown that they provide adequate crash protection.

- The pack must be constructed such that it could reasonably be expected to resist external fire (spilt fuel on the road) for at least 130 seconds to allow evacuation of the vehicle.

- Battery pack must have a semi-sealed ventilation system, usually containing a method of restricting moisture ingress, which is rated for the size of the pack.

- All battery packs must have contactors on all High Voltage (HV) connections such that neither the positive nor negative cables from the pack may be live when the pack is switched off.

- Functional Insulation monitoring must be fitted such that any breakdown in insulation of any HV component to the body or any non HV component is detected and the system is prevented from energising, or if the fault is found whilst running a safe shutdown procedure is initiated.

- Bonding straps or cables must be fitted on all HV units, packs, inverter etc, to ensure there can be no potential difference between any conductive surface that can be touched.

- Battery packs must have a Battery Management System that prevents over and under voltage on a cell level, ensuring the cells are balanced to the cell manufacturer’s specification.

- Battery packs must have a Battery Management Systems that prevents over temperature by reducing available power and shutting down if an upper limit, as proscribed by the cell manufacturer, is reached. Typically this will de-rate above 50C and shut down at 60C for lithium cells.

- The Battery Management System must be able to detect welded contactors. If detected then it must prevent start up and show a warning of EV Failure on the dash.

- The BMS must be able to detect excessive current and force a safe shutdown.

- All HV battery packs must have a suitable HRC fuse of automotive grade which is rated for the voltages and current expected.

- Cell tapping wires must be protected by a low current fuse (typically 0.2A) as close to the cells as possible such that the vast majority of the cell tapping wire from the BMS is protected. Cutting an modifying existing cell tapping wires should be avoided due to the risk of shorting wires, OEM module connections should be used where possible.

- All packs must have a means of isolating the HV, separate to the service contactors, to allow safe removal and handling of packs in the workshop or in emergency situations. It is highly recommended to use a Manual Service Disconnect which physically removes a link in the HV battery chain. Alternatively an additional contactor may be fitted to provide the same function, this will be powered via an isolator switch with a lockout mechanism (provision for padlocking etc.) or a removable link, the isolator may disable multiple packs where more than one pack is fitted in a vehicle.

- The location of MSDs or isolator switches must be clearly labelled on the vehicle in a location that is reasonable to expect emergency services to look, such as under the bonnet. The location information will also be logged in the build register and also in the information pack handed to the customer, it may also be issued to emergency services.

H. Charging systems

- Charging ports must be mounted such that they will not bend or break even if the charging cable is tugged. There must be a way for the plug to be locked in place (e.g. solenoid for Type 2 based sockets, latching lug for Type 1) and a detection system such that no current is passing the charging pins when the plug is disconnected. A visible charging indicator must be fitted.

- Where DC charging is fitted the cables from the socket to the HV system must be isolated such that under normal drive mode the cables and DC pins in the charging socket are not connected to the HV system, e.g. fitting two contactors to the DC charging cables.